Protean360+: An Advanced Electric-Drive Corner Module Designed for Next-Generation Urban Mobility Pods

Transport-as-a-Service urban mobility is gaining momentum and the need for a new class of urban transport vehicles. Whether shared or private, for passengers or goods deliveries, human-driven or autonomous, these new vehicles will require new technologies to be fit for purpose. The Protean360+ corner module was borne from the company’s innovative thinking about meeting the requirements for these next-generation urban vehicles.

The Protean360+ is an advanced electric-drive corner module designed for next-generation urban mobility pods with the following specs:

- Limitless 360-degree-and-beyond steering provides exceptional vehicle manoeuvrability.

- Pneumatic ride-height control enables ‘kneeling’ for stepless kerb-to-vehicle access.

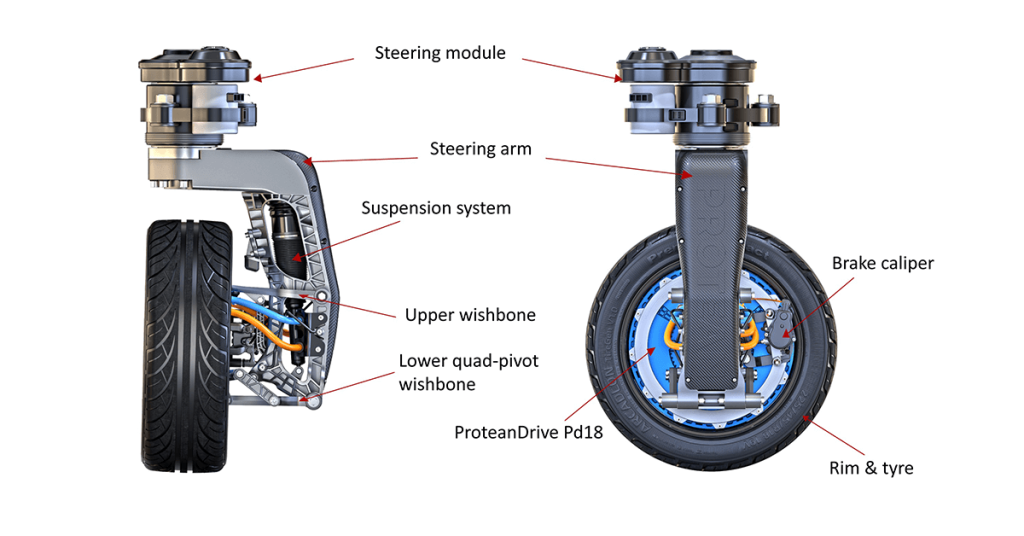

- Patent-pending quad-pivot lower wishbone design allows ultra-compact suspension setup.

- The fully integrated in-wheel motor delivers power with maximum efficiency

- The module enables front, rear and side access into vehicles

- The single module design is common across all four corners of the vehicle

Limitless 360-Degree Steering Capability

The capability for each wheel to be steered through and beyond 360 degrees without limitation

gives the vehicle an unprecedented manoeuvrability level. It means that the vehicle doesn’t

need to stop-steer-move when performing complex manoeuvres, ensuring smooth,

uninterrupted progress for passengers. It also means the vehicle can spin through 360 degrees

within its own footprint, helping it negotiate environments such as extremely tight urban streets,

parking lots and loading bays. It allows ultimate precision in manoeuvrability for the final metre

when approaching the kerb to park up.

The 360-degree steering capability is made possible by a patent-pending rotating interface that

sits above the corner module’s main arm. The top of the rotating interface is fixed to the vehicle, and the lower interface is fixed to the module arm.

Novel Twin-Knuckle Suspension for Compactness

The suspension system’s primary challenge was the compact packaging required to ensure

that the system takes up the minimum internal space, facilitating improved access for people with

reduced mobility or greater cargo capacity. To achieve this compactness, the development team

conceived a novel multi-link design with an additional lower wishbone pivot.

The patent-pending quad-pivot double-wishbone ’spider’ movement enables high-strength force transfer with compact packaging and full-range suspension travel.

This novel suspension packaging allows optimum geometry and additional articulation in the

lower suspension arm to achieve the desired kinematics while retaining the all-important

package compactness. It also allows the suspension system to exhibit identical behaviour and

performance in all directions of travel.

As a result, a single common module design is optimised for all four corners of the vehicle,

negating the need for left and right or front and rear versions, thereby reducing development and

production costs.

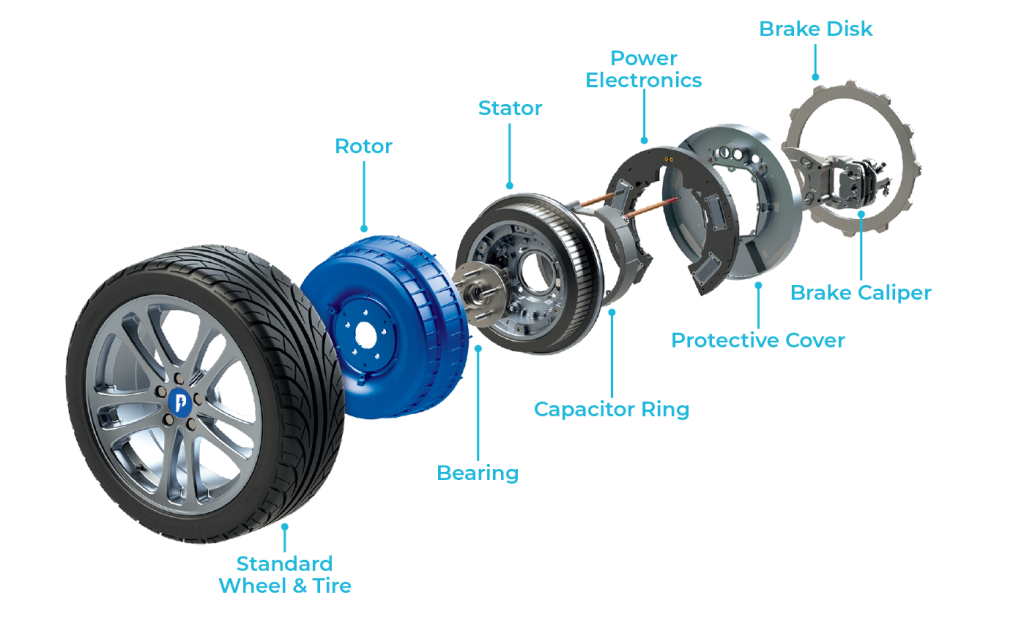

Super-Efficient, Fully Integrated in-Wheel Motor

Electric propulsion is provided by the ProteanDrive in-wheel motor, a highly integrated patented

design that provides maximum efficiency and flexibility and that includes all the core technology

of an electric driveline within a single unit. It is estimated to be significantly more efficient than

alternatives, such as e-axle solutions, thanks to eliminating driveline losses.

In-wheel motors also offer greater dynamic control of the overall power and torque delivery.

They can apply positive or negative torque within milliseconds, meaning the improved performance

of ESC, ABS and traction control systems, which benefit safety, stability and stopping distances

(typically 7% shorter, according to an independent study). Furthermore, there is a greater redundancy level, especially in four-motor setups, as torque load can be transferred if problems occur

in any one motor.

NEXT UP IN NEWS

- Top 5 Safest Cars You Can Buy Right Now

- Lucid Motors Presents a Behind-the-Scenes Look Inside Its Brand New AMP-1 Factory, Showcasing Production Processes of the Upcoming Lucid Air for the First Time

- Stellantis To Delay Production of Ram 1500 Classic Pickup Trucks Due To Chip Shortage

- GMC Unveils Refreshed Terrain for 2022, Featuring Rugged Off-Road Trim Option That Completes the Set

- The Battery That Will Revolutionize Electric Vehicles and Aircraft

Comments are closed.